4 Reasons Why a Pendulum Bucket Elevator Solution Is Beneficial

Home / 4 Reasons Why a Pendulum Bucket Elevator Solution Is Beneficial

4 Reasons Why a Pendulum Bucket Elevator Solution Is Beneficial

Gough's Swinglink® Pendulum Bucket Elevator is an alternative to inclined belt conveyor systems for transferring bulk product from and to different heights. The Swinglink® uses a continuous sequence of free-swinging buckets and is especially suitable for moving free flowing granular materials consistently and reliably in complex production layouts.

Typical industrial uses for bucket elevators include conveying powders, ingredients and partly-finished products e.g. wrapped sweets for food production but also for pharmaceuticals, chemicals, plastics and recycled materials. Even extremely delicate product such as crisps need that smooth and gentle handling without any loss of a product’s shape. Gough can provide buckets made of food-grade polypropylene, metal detectable polymer and stainless or carbon steel to meet these various application needs.

Typical industrial uses for bucket elevators include conveying powders, ingredients and partly-finished products e.g. wrapped sweets for food production but also for pharmaceuticals, chemicals, plastics and recycled materials. Even extremely delicate product such as crisps need that smooth and gentle handling without any loss of a product’s shape. Gough can provide buckets made of food-grade polypropylene, metal detectable polymer and stainless or carbon steel to meet these various application needs.

Here are the four main reasons why a bucket elevator layout is beneficial.

1) Flexibility

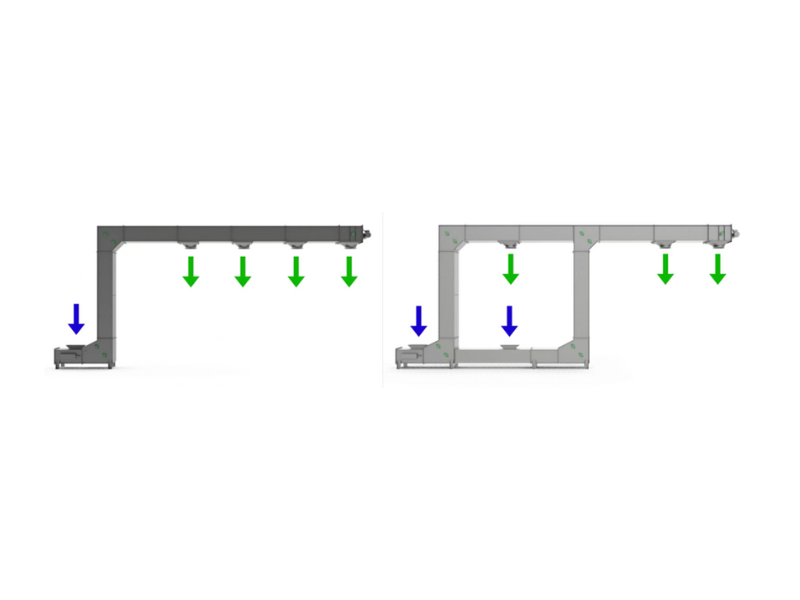

Pendulum bucket elevators benefit using modularity and flexibility. That means they can be designed with a near-infinite number of possible configurations to transfer product between processes in tight or difficult-to-modify production environments. The modular design of our elevators allows material to traverse almost any objects such as walkways, machines and floor levels. It is also possible to manufacture specific corner sections that will allow inclined conveying if required.

2) Protected Internal and External Elevating

Where production processes are split between floor levels, inclined belt conveyor may be used, but they consume more floor space and can be difficult to work into constrained production layouts. Pendulum bucket elevators, on the other hand, have a very modest footprint, avoiding the difficult-to-use space beneath angled belts for example. They can easily extend to multiple floors if required (internally or externally), the modular design allowing movement up or down without limitation.

As our bucket elevator systems can be panelled to house its chains, sprockets and buckets, they can be situated externally, leaving more usable production space inside the factory. Removeable inspection panels can be supplied in powder-coated carbon steel, grade 304L or 316L stainless steel, clear polycarbonate, and even stainless steel open mesh to suit different customer and safety requirements.

3) All Shapes And Sizes

Complex production environments may and material travel routes can be complicated where many obstacles between inlet and discharge points cannot easily be removed due to existing production and building layouts. Gough can supply many elevator configuration types including J, Z (true Z or vertical), T, C and many more. Bucket elevators can also accommodate vertical and inclined solutions with loop systems, as well as stair and step configurations.

4) Multiple Inlets and Discharge Points

Large or complex plants may have multiple inlet points, converging product streams from multiple feed machinery. Similarly, discharge may need to be split into different output silos or a variety of post-process layouts for example, with multiple high volume packing lines. The Gough Swinglink® Pendulum Bucket Elevator can be configured to incorporate many transfer features, all design in-house at Gough Engineering.

What Next?

At Gough Engineering, we provide customisable bucket elevator solutions for a wide variety of applications. To find out more, please contact us today.

Other Articles

- From rubbish to recycled

- Circular separators versus linear separators

- The power of gentle handling with bucket elevators

- Meeting the surge in demand for grain-based foods

- Overcoming rising energy prices

Contact Gough

Contact our team of highly skilled engineers to discuss your custom requirements today. .

Enquire TodayOther areas you may be interested in…

Have An Enquiry

Call our team of highly skilled engineers to discuss your requirements on 01782 493127 or fill out our online enquiry form.

Enquire Today