What Advantages Do Pendulum Bucket Elevators Have Over Other Conveying Methods?

Home / What Advantages Do Pendulum Bucket Elevators Have Over Other Conveying Methods?

What Advantages Do Pendulum Bucket Elevators Have Over Other Conveying Methods?

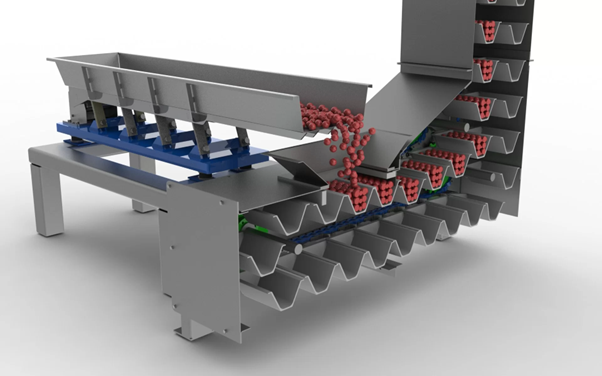

Pendulum bucket elevators are designed to provide mainly continuous vertical and horizontal conveying of free-flowing bulk materials. The Gough Swinglink® Bucket Elevator was originally designed and patented in the 1980s and has since provided reliable conveying of powder products in food, chemical, pharma and other sectors. While the bucket elevator is not the only means of transporting materials on the production line, its proven efficiency and design flexibility make it a good choice for many applications.

1) Footprint

Bucket elevators offer a very effective use of the ground area in industrial settings where space is at a premium. Vertical conveying methods generally have a smaller footprint than, for example, inclined belt and bucket conveyor systems. This vertical space saving feature is crucial within production lines that have very compact equipment arrangements.

2) Handling

The movement of the Gough Swinglink bucket elevator offers smoother and more gentle material handling than other conveyor systems. The general design of a Swinglink® elevator reduces spillage or disruption of its contents, enabling them to preserve a product’s integrity especially for fragile or delicate products. As products are transferred out of the buckets, the Gough elevator similarly provides gentle handling where required. The patented design allows smooth tipping motion that helps to retain the shape and state of the bucket contents. Optimum handling can also be aided by choosing the right bucket material. Food grade polypropylene, metal detectable polymer and stainless or carbon steel buckets are all available, depending on application.

3) Performance

The elevator can also be tailored to meet many different production rates utilising different bucket sizes from 9” to 36” in length. Throughput of a bucket elevator can range from relatively large product material quantities, measured in tons per hour, down to much smaller quantities and where perhaps product volume in litres is a key factor, rather than just its bulk density or weight. Buckets can be easily removed, cleaned and replaced therefore reducing downtime.

4) Adaptability

The Gough Swinglink is also suitable for use in larger packing lines where feeds can come from different sources and delivered to different process locations using multiple tip points. Multiple inlet and outlet points may be used to adapt to different product sorting requirements such as controlling directional flow, allowing delivery to alternative post-process equipment. It is even possible to incorporate an adjustable discharge position.

5) Extensibility

The Gough bucket elevator can be tailored to meet different production environments. The modular design allows horizontal or vertical movement to be extended with varying length sections. Specially designed corner sections are also possible. In fact, with infinite configuration possibilities, optimal transfer of product in virtually any layout is possible.

6) Less Waste

Product spillage can be wasteful, and the ability to transfer materials continuously around corners and angles is one reason why, for example, belt conveyors are sometimes preferred. However, Gough's bucket elevators can eliminate spillage by closing any gaps between buckets during travel with a special overlapping lip. As well as preventing waste, this helps to improve cleanliness in the elevator and surrounding areas and also retains good throughput.

Find Out More

To learn more about the Gough Swinglink® and the advantages of them in your production line, please contact us today.

Other Articles

- From rubbish to recycled

- Circular separators versus linear separators

- The power of gentle handling with bucket elevators

- Meeting the surge in demand for grain-based foods

- Overcoming rising energy prices

Contact Gough

Contact our team of highly skilled engineers to discuss your custom requirements today. .

Enquire TodayOther areas you may be interested in…

Have An Enquiry

Call our team of highly skilled engineers to discuss your requirements on 01782 493127 or fill out our online enquiry form.

Enquire Today